One of the first principles of sustainable and environmentally friendly architecture is to reduce the embodied energy of the materials used in construction. Embodied energy is the sum of all energy inputs–for manufacturing, all transportation, human resources etc–that are needed to make a product. Transportation plays a major role here so, if a material can be sourced locally, it can reduce the embodied energy (and carbon footprint) quite substantially.

With services like Google Maps available to us, it has become very easy to get data like distance from source to site

Mahatma Gandhi–an instinctive environmentalist if ever there was one–exhorted people to build with materials that were available within a 50km radius. His reasoning may have had little to do with a scientific knowledge of embodied energy and more to do with his lifelong devotion to the concept of localisation and decentralisation. Regardless, if we keep the 50km limit in mind for most materials, we can prevent the burning of a lot of fossil fuel.

An additional advantage is that, as transportation costs are minimal for local materials, they are also usually more affordable than something that comes from a great distance. Besides, if you’re planning on using local labour then, their familiarity with it leads to a sturdier and better finished project.

However, we must always weigh our options with an open mind. As an example, for corrugated roofing, I refuse to use asbestos sheets on principle. For a project outside Mumbai, I considered getting a non-asbestos alternative from Coimbatore. However, we eventually settled on a flat sheet made from bagasse by a Pune company even though it needed a heavier steel framework to support. Why was that?

The corrugated roofing system would have had less embodied energy even after transportation but, the sheets themselves could only be bought in bulk from the manufacturer so, if the project ever needed just a single extra sheet at any stage, we’d have to call for an entire truck — even if it was almost empty. That, in the end, tipped the scales in favour of the more readily available Ecoboard.

Flyash bricks can be made to look like traditional bricks if you add a little red-oxide in the mix. This is useful if you want to keep the wall un-plastered like we did for the RaBV Bungalow.

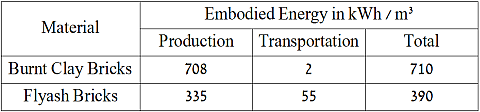

Another time, for the [RaBV] bungalow, the clients were willing to pay the extra transportation cost to bring in flyash bricks, from Wada in Thane district, to Karjat — a distance of approximately 100km. Apart from the fact that manufacture of clay bricks leads to the loss of precious topsoil, the overall embodied energy is substantially lower despite the fuel burnt for carrying them over the distance. Here is the basic calculation:

So, as you can see, there are no hard and fast rules when it comes to distance. Each case has to be looked at individually and assessed on merit. We also don’t always have ideal situations but we must, at the very least, aim to minimise the embodied energy of our structures.

So, as you can see, there are no hard and fast rules when it comes to distance. Each case has to be looked at individually and assessed on merit. We also don’t always have ideal situations but we must, at the very least, aim to minimise the embodied energy of our structures.