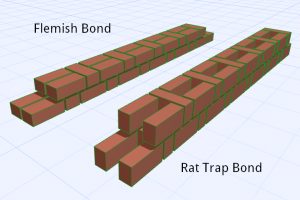

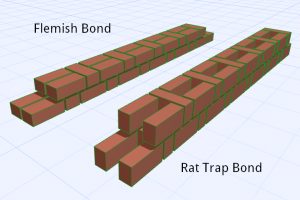

Just in case I’ve got you visualising rodents scurrying about where they’re not wanted, ease your mind; the rat trap bond I’m talking about is simply a method of laying bricks when building a wall. It’s similar to the common “Flemish” bond but instead of putting the bricks on their face, they are placed on their edges. This leads to cost savings because less bricks and cement are needed which, in turn, reduces the embodied energy of the wall.

Bricks are laid on edge to create an air gap between two layers

Laurie Baker took every opportunity to try and make people realise the value of this method but, by and large, the 20-25% saving in brick doesn’t seem to have been appealing enough. The rat trap method of construction was popular in England until the start of the 20th century but sustained lobbying by the brick-making industry convinced people that that it was not strong enough to build load-bearing walls.

That is rubbish of course; it’s strong enough for one and two storey buildings as has been proven over and over again by Laurie Baker’s lasting work. But masons too are not usually happy about adopting this system and come up with all sorts of excuses to try and avoid it. I have to admit that, till date, I have not pushed hard enough against their inertia but now I’ve just got one more reason to do so.

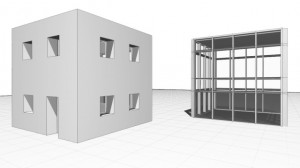

For the ShKo bungalow at Karjat, I plan to use the rat trap walls and wanted to know just how much difference they would make thermally. Nobody seems to have done a calculation of the difference — at least there was none that I could find. So, armed with some data from thermal calc and the energy evaluation component of ArchiCAD, I tried to do just that.

Taking just a simple 3m x 3m structure with no openings, I ran a calculation for both types of wall. Result: average U-value of the structure’s outer shell dropped about 15% compared to conventional walls and the energy required for cooling also fell by about 8%. The difference was exaggerated because the model had good roof overhangs to shade the walls.

Still, when you think about it, 8% is nothing to scoff at. In addition, the embodied energy is reduced quite dramatically and, of course, Laurie Baker’s original reason for using the rat-trap bond still stands — the wall is simply cheaper to build.

Now, I just have to go and steam-roll the masons into learning a new technique.

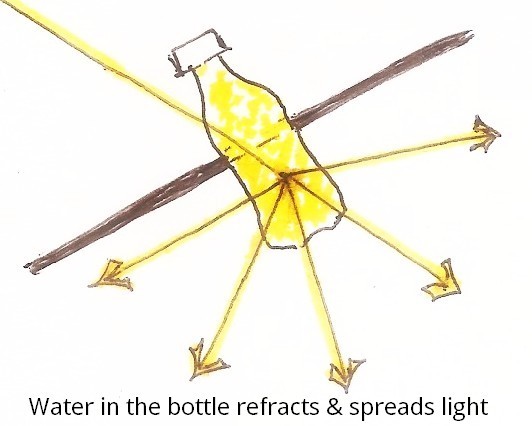

Sometimes, a simple idea can be immensely powerful. Maybe the bottle light is not something that makes a huge difference to your life or mine but, for those who live in shanties with little or no electricity, this is a godsend.

Sometimes, a simple idea can be immensely powerful. Maybe the bottle light is not something that makes a huge difference to your life or mine but, for those who live in shanties with little or no electricity, this is a godsend. Essentially, one fills a used, transparent, plastic bottle with water and a little bleach (to prevent algae) and sticks it into a hole in the roof. That’s it. Oh, and don’t forget to seal the edges of the hole.

Essentially, one fills a used, transparent, plastic bottle with water and a little bleach (to prevent algae) and sticks it into a hole in the roof. That’s it. Oh, and don’t forget to seal the edges of the hole.

Yesterday was my day to visit Bombay Exhibition Centre at Goregaon for this year’s

Yesterday was my day to visit Bombay Exhibition Centre at Goregaon for this year’s

Reading an

Reading an